Eco Strumet

Modern solutions for sustainable and safe production

Environmental protection

Our facility does not emit volatile organic compounds. All process tanks are housed in a sealed chamber, from which vapors are purified in an absorber. The tanks are equipped with a safety system to prevent chemical leakage into the environment in the event of a leak.

The hot-dip galvanizing plant, like the electroplating plant, is wastewater-free, meaning process solutions operate in a closed loop. At the end of 2019, we began installing photovoltaic panels on the roofs of our production halls. We continuously monitor pollutant emissions.

Ecological product

Ecological service

Ecological process

Ecological process

Technologies supporting ecology and production efficiency

- A 1.5MWh photovoltaic installation installed on the roofs of the production halls allows for covering 20% of electricity demand.

- Modern laser cutting machines ensure maximum material utilization, reducing waste to a minimum.

- Thanks to its own treatment plant, technological solutions work in a closed circuit and the plant does not produce industrial wastewater.

- The hot-dip galvanizing installation was equipped with heat recovery.

- Chemical treatment processes in the hot-dip galvanizing plant take place in a sealed capsule equipped with an absorber that captures all fumes.

- Waste generated on the plant premises is carefully sorted and sent for recycling.

- The welding shop is equipped with a modern, high-efficiency filtration system that prevents dust emissions into the atmosphere.

- Drinking water is filtered on-site from the network installation, which prevents the production of several tons of waste in the form of PET bottles every year, and the water delivery vehicles do not emit several hundred kilograms of CO2.

- The production halls are lit with energy-saving LED lamps.

- Our own laboratories allow us to continuously optimize processes, reducing the consumption of raw materials and reducing the amount of waste.

- The use of reusable industrial cleaning cloths significantly reduces the amount of waste generated.

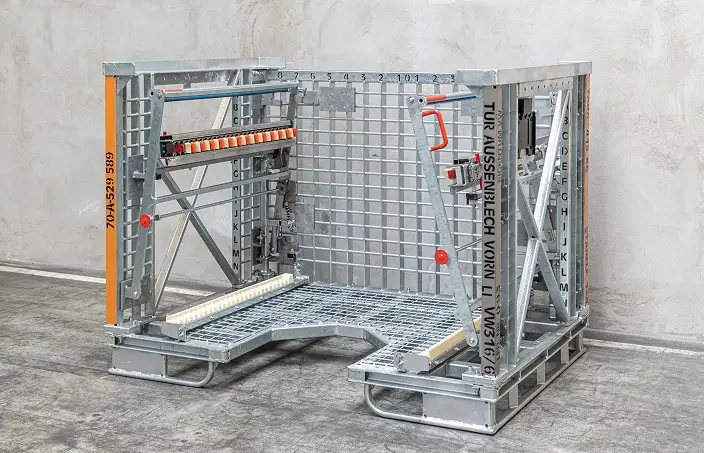

Ecological product

Transport and storage containers are primarily made of steel, a material that ensures high durability and is also recyclable. The containers' robust construction and stackability allow for efficient use of warehouse and transport space, reducing greenhouse gas emissions. Our products require no packaging, so we avoid using packaging materials such as paper, foil, or wood.

Ecological service

The hot-dip galvanizing plant, which has been operating since 2008, protects over 22,000 tons of steel structures from corrosion each year. This is enough to

building three Eiffel Towers. The zinc coating protects the steel for decades, avoiding costly and environmentally harmful repainting.