Electroplating shop

A hanging line for larger elements and a drum line for small details

How does our electroplating plant in Silesia work?

Galvanic galvanizing plant Launched in mid-2020, it provides services in the electrolytic application of decorative and anti-corrosion zinc coatings to steel structures. The galvanizing installation is one of the most modern of its kind in Poland.

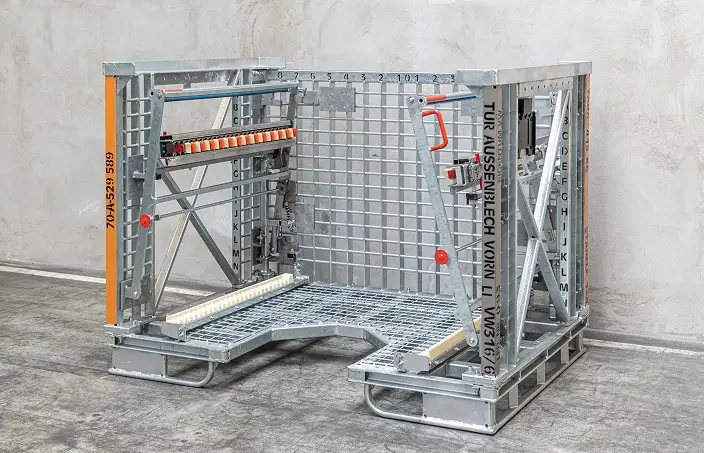

Our electroplating shop It consists of two lines – a hanger line for larger components and a drum line for smaller details. The hanger line allows for the galvanization of structures measuring up to 2.8 meters in length, 0.8 meters in width, and 1.8 meters in height. Both the hanger and drum lines are fully automated. Autonomous conveyors move the parts between the subsequent process tanks, and the bath parameters are continuously monitored by a computer system.

The appropriate composition of technological baths is supervised by chemists who have a professional laboratory at their disposal.

analytical.

Why is it worth choosing a galvanizing service?

The equipment and technologies used in the galvanizing plant allow for obtaining the highest quality zinc coatings. They also ensure high process efficiency, which translates into attractive prices and short lead times. One of the key principles of our business is environmental protection. Thanks to the use of an advanced and highly efficient purification system, technological solutions operate in a closed system, and the galvanizing plant produces no industrial wastewater.

New deadlines

Up to 100 kg

Delivery within 24 hours.

From 1T to 3T

Completion within 72 hours.

From 100 kg to 1T

Delivery within 48 hours.

Above 3T

Completion date determined individually. Daily throughput: 20,000 kg.

Galwanizernia Śląsk – why is it worth using?

We have the best

Available devices

and technologies

We are hiring

The best specialists

It does not have a negative impact

On the natural environment

Why is it worth using a galvanizing shop?

in Silesia?

Galvanic zinc plating allows for obtaining an aesthetic and uniform coating, The final thickness (3-25 micrometers) can be influenced by adjusting process parameters such as current flow and time. Before applying the coating, steel parts and structures submitted for galvanizing are carefully degreased and rust-free by acid pickling. The components are then placed in baths.

with an alkaline electrolyte, where a zinc layer is applied during electrolysis. In subsequent stages of the process, the zinc layer undergoes white, yellow, or titanium passivation, improving the adhesion of the paint coating. To increase durability, the coatings on the hanger line can be additionally sealed.

Gallery

Conditions for accepting the structure

If you plan to subject your structure to the galvanizing process, be sure to check whether it meets the required conditions.

| Guidelines | Description |

| 1. Chemical composition | Galvanic zinc plating allows for covering steel structures with a silicon (Si) content of less than 0.03 % or in the range of 0.15% – 0.25 % with an anti-corrosion layer of zinc. |

| 2. Surface condition | The surface of the structure should be free from scale, thick layers of rust, welding spatter, welding slag, silicone anti-spatter agents, paint contamination, grease and oil. |

| 3. Construction features | Suspension line: The structures should be able to be suspended using suspension hooks under the beam. The shape of the structure should allow for the free flow of process fluids into all spaces and their free flow out. |

| 4. Dimensions of the structure | Suspension line: The structure's dimensions must be less than or equal to the dimensions shown – 2.8 x 0.8 x 1.8 m (length x width x depth). If two dimensions are close to the limit, prior consultation is required. Maximum load weight is 600 kg per beam, and maximum load size is 1200 dm² per beam. Drum line: Minimum load 20kg per drum |

| 5. Vent holes | Structures made of closed-section elements should have vent holes to allow the free inflow of process baths during immersion and their free outflow during the structure's emergence at various stages of the process. The table below lists the size and number of vent holes in structural elements.

Ventilation holes can be made as triangular or semicircular cutouts in the profile walls. The drawings below illustrate the principles of placing vent holes.   |

| Guidelines and description |

| 1. Chemical composition |

| Galvanic zinc plating allows for covering steel structures with a silicon (Si) content of less than 0.03 % or in the range of 0.15% – 0.25 % with an anti-corrosion layer of zinc. |

| 2. Surface condition |

| The surface of the structure should be free from scale, thick layers of rust, welding spatter, welding slag, silicone anti-spatter agents, paint contamination, grease and oil. |

| 3. Construction features |

| Suspension line: The structures should be able to be suspended using suspension hooks under the beam. The shape of the structure should allow for the free flow of process fluids into all spaces and their free flow out. |

| 4. Dimensions of the structure |

| Suspension line: The structure's dimensions must be less than or equal to the dimensions shown – 2.8 x 0.8 x 1.8 m (length x width x depth). If two dimensions are close to the limit, prior consultation is required. Maximum load weight is 600 kg per beam, and maximum load size is 1200 dm² per beam. Drum line: Minimum load 20kg per drum |

| 5. Vent holes |

| Structures made of closed-section elements should have vent holes to allow the free inflow of process baths during immersion and their free outflow during the structure's emergence at various stages of the process. The table below lists the size and number of vent holes in structural elements.

Ventilation holes can be made as triangular or semicircular cutouts in the profile walls. The drawings below illustrate the principles of placing vent holes.   |

| Internal dimensions of the closed profile in mm less than: | Minimum diameter of holes in mm at opposite ends of the profile and their number: | ||||

| Round | Square | Rectangular | 1 | 2 | 3 |

| 15 | 15 | 20 x 10 | 8 | - | - |

| 20 | 20 | 30 x 15 | 10 | - | - |

| 30 | 30 | 40 x 20 | 12 | 10 | - |

| 60 | 60 | 80 x 40 | 20 | 12 | 10 |

| 80 | 80 | 80 x 60 | 20 | 18 | 12 |

| 100 | 100 | 120 x 80 | 25 | 20 | 12 |

| 120 | 120 | 160 x 80 | 30 | 25 | 16 |

| 160 | 160 | 200 x 120 | 40 | 25 | 16 |

| 200 | 200 | 260 x 140 | 50 | 30 | 16 |

| Internal dimensions of the closed profile in mm less than: | ||

| Round | Square | Rectangular |

| 15 | 15 | 20 x 10 |

| 20 | 20 | 30 x 15 |

| 30 | 30 | 40 x 20 |

| 60 | 60 | 80 x 40 |

| 80 | 80 | 80 x 60 |

| 100 | 100 | 120 x 80 |

| 120 | 120 | 160 x 80 |

| 160 | 160 | 200 x 120 |

| 200 | 200 | 260 x 140 |

| Minimum diameter of holes in mm at opposite ends of the profile and their number: | ||

| 1 | 2 | 3 |

| 8 | - | - |

| 10 | - | - |

| 12 | 10 | - |

| 20 | 12 | 10 |

| 20 | 18 | 12 |

| 25 | 20 | 12 |

| 30 | 25 | 16 |

| 40 | 25 | 16 |

| 50 | 30 | 16 |