Injection molding plant

Fast and reliable production of plastic components

How do we perform injection?

Injection molding is primarily used to produce products from thermoplastic polymers. The input material for production is polymer in granulated form. We use either virgin or recycled granulates, primarily from regrind production waste. The granulates can be colored in any desired way. We collaborate with leading granulate suppliers, ready to supply any currently known material. The most commonly used materials are PE, PP, PS, SB, SAN, ABS, PA, TPE, and TPU.

What is the injection technique?

The manufacturing technique involves plasticizing the material and injecting it into a mold, usually equipped with a cooling system, where the material cools and solidifies. After opening the mold, the finished product is removed. Strumet's plastic injection department is equipped with three Tederic injection molding machines. These are modern, high-performance machines with clamping forces of 130, 350, and 700 tons. The maximum shot weight of the largest machine is almost 3,400 g.

The operation of the injection molding machines is supervised by experienced operators supported by technologists in optimizing the operating parameters of the devices.

Injection molding - why is it worth using?

Injection molding is the most popular technique for molding plastic parts. It's indispensable for large-scale and mass production. High efficiency combined with a small amount of reusable waste contribute to the process's effectiveness. The low cost of producing a single part is unattainable with any other technique. Injection molding allows for the production of finished components and products of high quality and repeatability.

requiring no additional processing. The injection molding technique is also exceptionally environmentally friendly, as no harmful emissions occur during molding. The plastic is plasticized by heating the granulate with electric heaters, which are partially powered by energy from our own photovoltaic installation.

Let's start a conversation

about solutions for your business.

Advantages of producing plastics using injection molding technology

Production of even very complex shapes.

Extremely fast - a single element takes only a few seconds.

No negative impact on the environment.

Repeatability of products with identical shapes.

High quality - surfaces of created products.

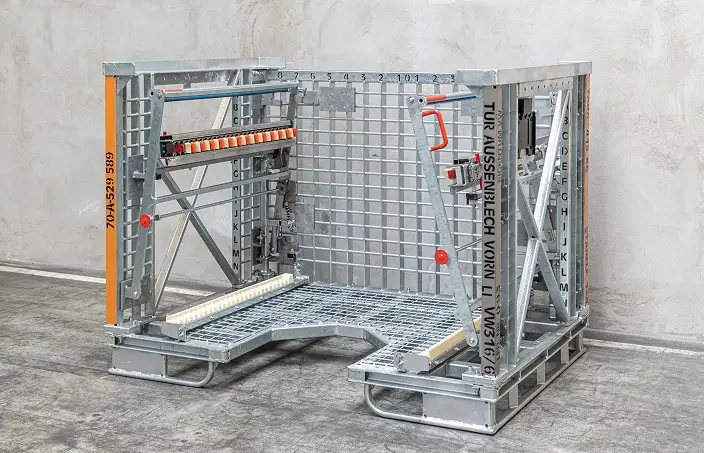

Plastic injection molding

[machinery park]

| D 130 injection molding machine | D 200 X3i injection molding machine | D 350 injection molding machine | D 400 injection molding machine | Injection molding machine D 500 x2 | D 700 injection molding machine | |

| Injection volume [cm3] | 270 | 442 | 992/td> | 1347 | 2031 | 3715 |

| Injection weight [g] [PS] | 246 | 402 | 903 | 1226 | 1848 | 3381 |

| Clamping force [kN] | 1300 | 2000 | 3500 | 4000 | 5000 | 7000 |

| Minimum mold height [mm] | 160 | 220 | 280 | 280 | 320 | 400 |

| Clamping force [kN] | 460 | 560 | 700 | 750 | 8000 | 980 |

| Minimum mold height [mm] | 420x420 | 530x530 | 680x680 | 730x730 | 820x820 | 960x960 |

| Dimensions |

| Specification |

| Welding device |

| Destiny |

| Material |

| Number of machines |

| Double robot with two rotary tables | Single robot with two rotary tables | Single robot with two fixed tables | Single robot with two fixed tables |

| 3300 x 1300 mm | 1550 x 1300 mm | 1200x1200 mm | 1200x1200 mm |

| two robot arms that weld simultaneously | one robot arm | one robot arm | one robot arm |

| FRONIUS TPS4000 | FRONIUS TPS4000 | MERKLE | FRONIUS TPS 400i |

| larger components, MIG/MAG | smaller elements, MIG/MAG | smaller elements in several operations/MIG/MAG | smaller elements in several operations/MIG/MAG |

| carbon steels, chromium-nickel steels | carbon steels, chromium-nickel steels | carbon steels, chromium-nickel steels | carbon steels, chromium-nickel steels, aluminum |

| 3 | 2 | 5 | 1 |

Gallery

We care about the environment

At Strumet, we believe that industrial development can go hand in hand with environmental protection. Our goal is to create solutions that are not only reliable and durable, but also environmentally friendly.

Are you looking for a reliable partner?

for industrial cooperation?

for industrial cooperation?

Contact us – we will prepare an offer tailored to your needs!

Contact form