Electroplating, while it may sound complicated, plays a crucial role in the electronics industry. This chemical phenomenon has many applications that may surprise you.

Electroplating in the electronics industry

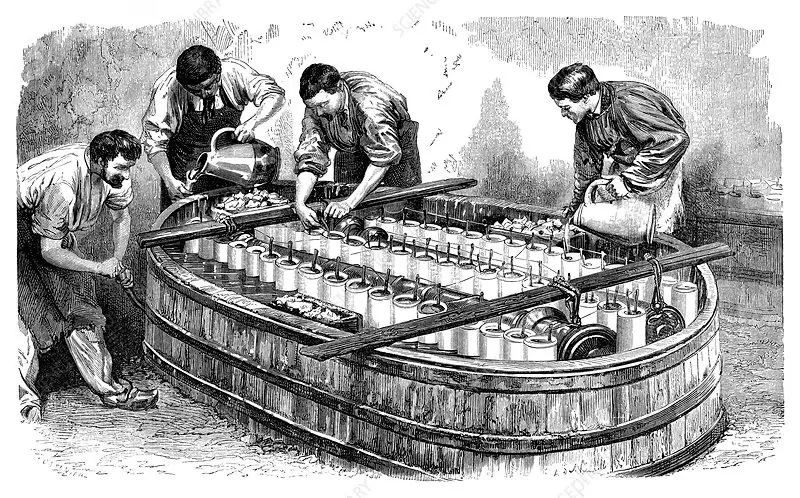

Electroplating is an electrochemical process that plays a key role in the electronics industry.This is a technique that involves coating metal objects with a layer of another metal using an electric current. Although initially plating Originally used primarily in the jewelry industry, it now finds applications in many fields, including the electronics industry. In the following article, we'll present five amazing applications of electroplating in this industry.

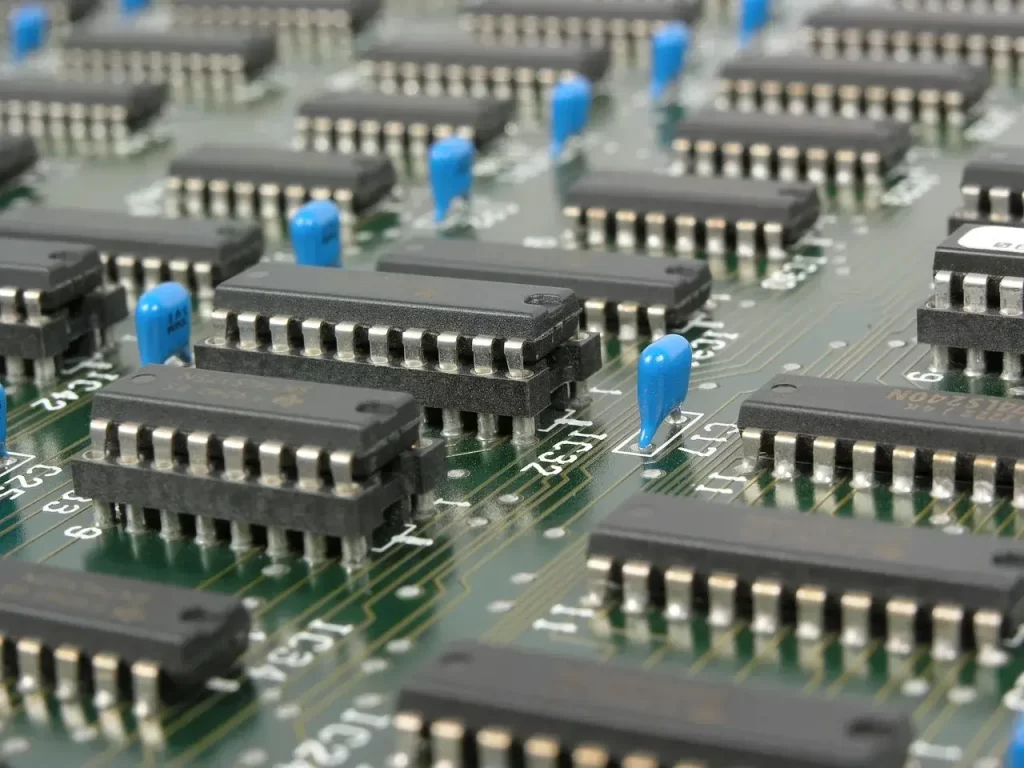

1. Protective Coatings

One of the most important applications of electroplating in the electronics industry is the creation of protective coatings on metal components such as electronic device housings and printed circuit boards. These coatings are designed to prevent metal from corroding and rusting., which is crucial for the durability and reliability of electronic components. Electroplating allows thin layers of metals, such as zinc or nickel, to be applied, effectively protecting against damage caused by external factors.

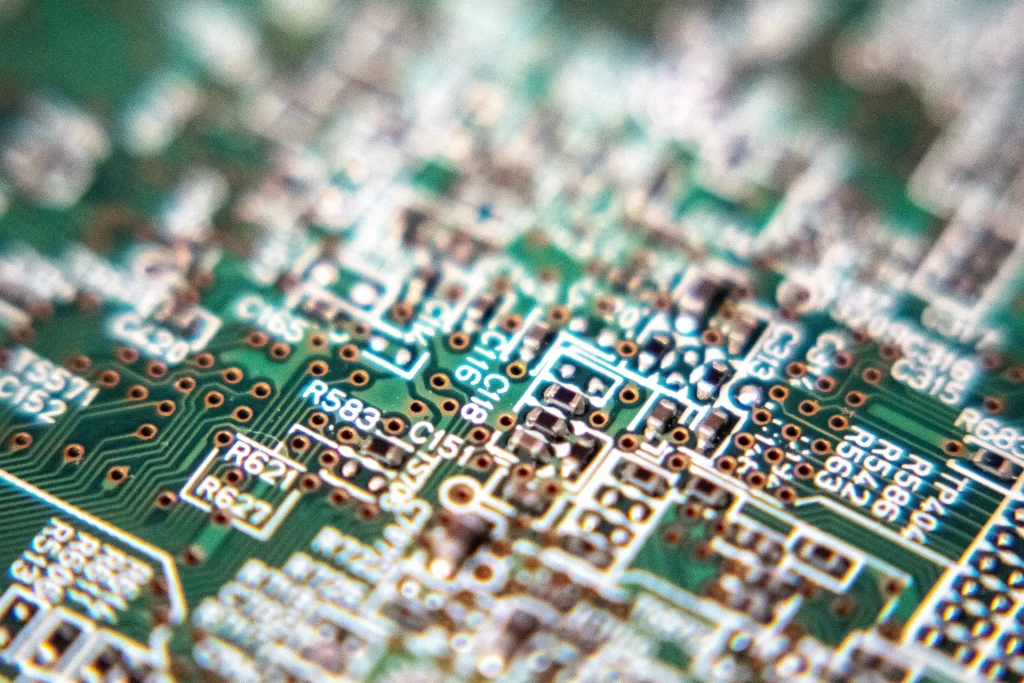

2. Making Electrical Connections

In the electronics industry, not only protective coatings are important, but also the creation of low-resistance electrical connections. Galvanization enables the creation of durable and reliable electrical connections., which is essential in the production of integrated circuits, cables, and other electronic components. Electroplating allows for precise control of the thickness and quality of metal layers, which is crucial for the proper functioning of electronics.

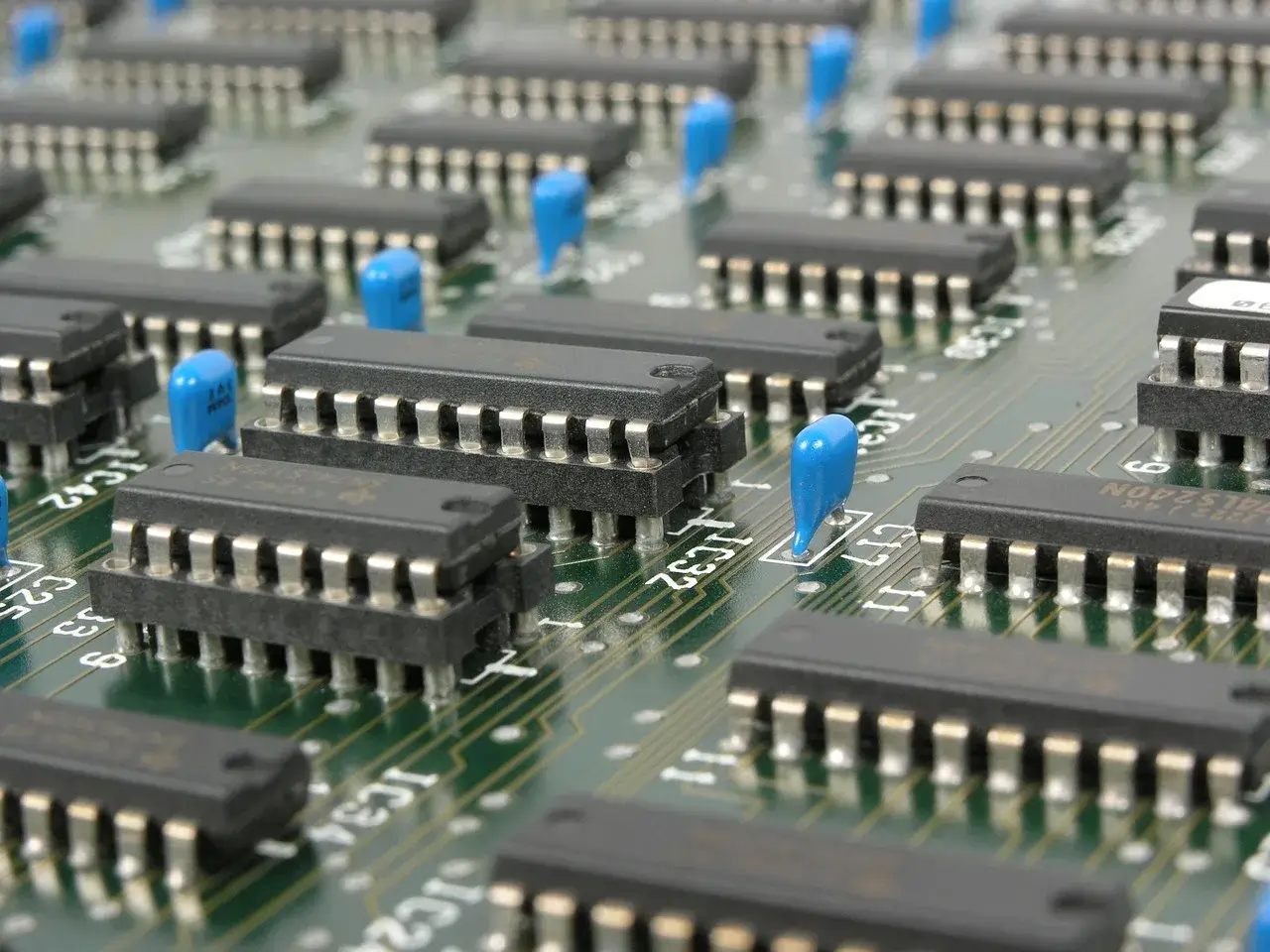

3. PCB (Printed Circuit Board) Production

Printed circuit boards (PCBs) are the foundation of many electronic devices. Electroplating in the electronics industry is an integral part of the PCB production process.This process involves coating conductive layers on dielectric substrates, creating electrical paths that allow current to flow between various components. PCBs are the core of electronics, so precise and reliable electroplating is crucial for producing high-quality boards.

4. Creating Fasteners

Electroplating in the electronics industry often uses connectors to connect different components.. Electroplating allows the creation of fasteners such as pins, which are used to ensuring not only mechanical connection but also electrical contact between partsThis technique allows you to create fasteners with excellent electrical conductivity and durability.

5. Surface Finishes

Aesthetics and surface finish matter, especially when it comes to consumer electronics. Electroplating in the electronics industry allows you to create various surface finishes, such as chrome plating, gold plating or silver plating. These finishes not only give the products an attractive appearance, but also protect them against damage and the influence of weather conditions.

Why is it worth performing electroplating in the electronics industry?

Electroplating in the electronics industry plays a key role in influencing durability, reliability and aesthetics