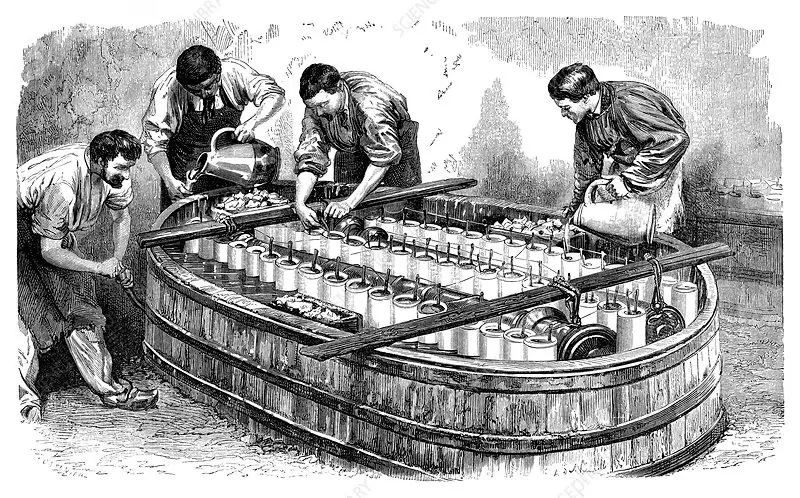

In today's article, we'll address the problem of current reflection at the point of contact between the hanger and the workpiece during the galvanizing process. This potentially harmful effect can lead to numerous complaints and customer dissatisfaction. We'd like to take a closer look at this phenomenon and present a solution that can benefit both producers and users of galvanizing services.

Case Study: Current Reflection at the Point of Contact between the Pendant and the Detail

When fasteners are electroplated, especially when attaching items with varying surface finishes, current reflection often occurs. This phenomenon can result from uneven current conduction through the metal components, leading to uneven zinc coverage and potential damage to the protective coating.

Causes of Current Kickback

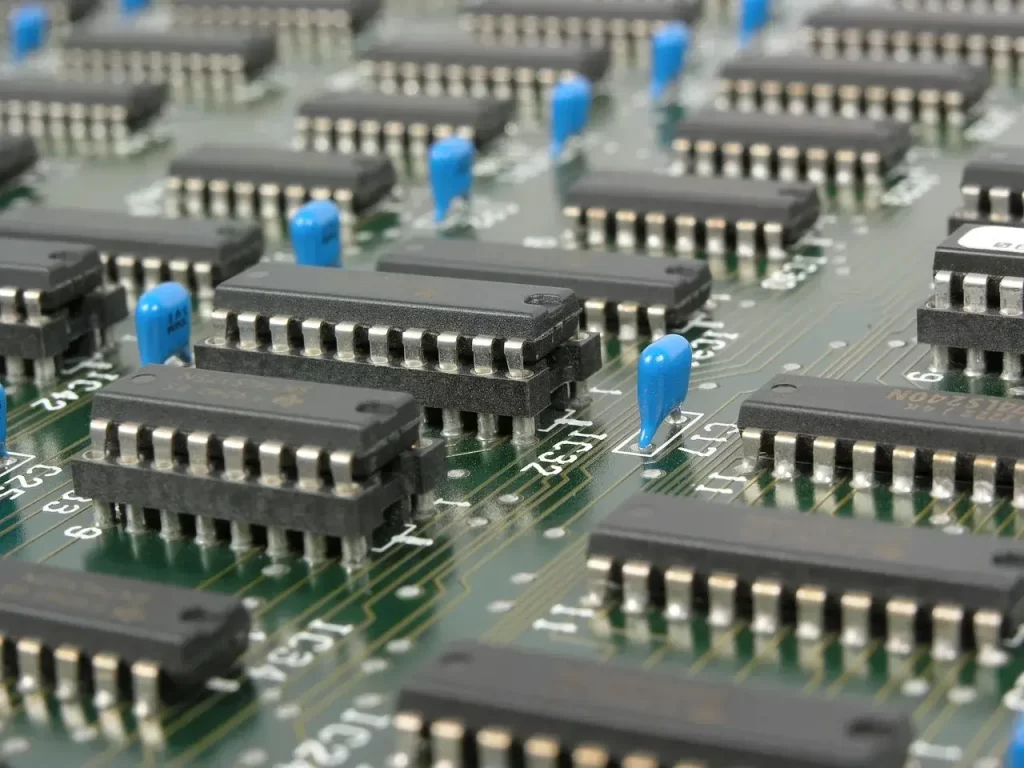

Uneven current wire: The surface of the pendant and the detail may have different electrical conductivity properties, leading to non-uniform current flow and reflection.

Improper mounting: Incorrect positioning of the detail in the pendant may lead to poor electrical contact, increasing the risk of current reflection.

Excessive current density: Too high a current density can intensify the reflection phenomenon, especially in areas with a large electrical potential difference.

Solution: Using a Metal Alloy with a Smaller Conducting Surface

To effectively eliminate the problem of current reflection at the point of contact between the hanger and the detail, we propose the introduction of a special metal alloy with a smaller conductive surface. This innovative approach minimizes the risk of under-galvanization in key areas, such as the hook-to-part interface. This method allows for more uniform zinc coating, resulting in excellent corrosion protection and greater customer satisfaction.

Current Reflection at the Contact Point – Summary

In today's article we discussed the problem of current reflection at the point of contact between the pendant and the detail in the galvanizing process We also presented a solution in the form of using pendants made of a suitable metal alloy. We believe that our experience and advanced technologies can help minimize this problem and ensure high-quality service for our customers.

For further questions or information, please contact us. We are happy to provide assistance and advice on any matter related to galvanic galvanizing.