Hot-dip galvanizing of large-scale structures begins where the standard galvanizing approach is no longer sufficient. The steel is immersed in liquid zinc at a temperature of approximately 450°C triggers a metallurgical reaction identical to that of small components, but the scale of the structure introduces entirely different technological challenges. In the case of large-scale structures, the scale itself begins to work against simple technological schemes. The component's mass, arm length, and weld arrangement prevent the steel from heating evenly when immersed in liquid zinc. Temperature differences between individual zones directly affect the rate of iron and zinc diffusion, and thus the coating's growth pattern. The effect is immediately visible, as zinc does not behave identically across the entire surface, even with the same bath parameters. This is why galvanizing large-scale structures requires an individual approach to each component, rather than replicating the same production protocols.

Logistical challenges: transport and handling of heavy items

For large-scale structures, logistics begin even before the element enters the galvanizing plant. External transport often involves oversize shipments, route planning, travel times, and appropriate structural protection. Stresses can already occur at this stage, only to become apparent later when the steel enters the galvanizing bath and reaches temperatures approaching 450°C.

Once the structure is accepted into the plant, it is crucial internal logistics. We operate on overhead cranes with lifting capacities exceeding 10 tons, using trolleys and slings designed for specific dimensions and gravity points. The method of suspending and guiding the element directly impacts the stability of the structure during immersion. In large-scale galvanizing, every movement of the element within the hall is part of the technological process, not just a transport operation.

Key stages of preparing the structure for galvanizing

In large structures, preparation determines everything that happens in the zinc bath. Planning is essential at the design stage. technological, filling and venting holes. Their purpose is to allow the free flow of liquid zinc and the removal of air and gases. The lack of appropriate openings leads to local underzincification, and in extreme cases, violent reactions during immersion.

The surface condition has a direct impact on the galvanizing process. Large structures often undergo various stages of processing and storage, so we remove rust, scale, paint residue, and welding flash before processing. Even slight differences in preparation are immediately reflected in the coating's structure. Zinc reacts directly with steel and reveals faults in the first moments of contact with the bath.

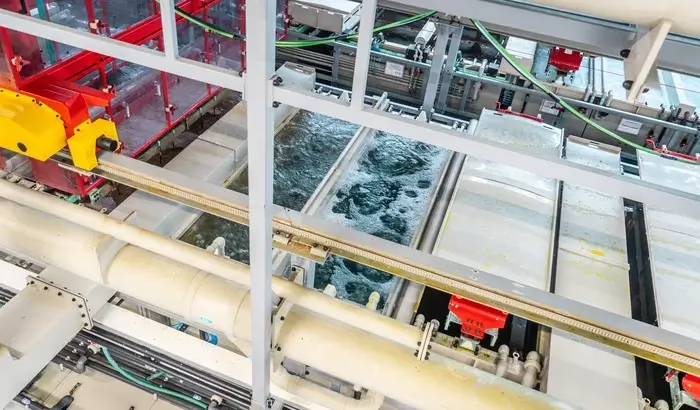

Dimensions of the galvanizing tank and the double-dipping technique

One of the main technological limitations in large-scale galvanizing is the dimensions of the galvanizing tank. Standard lines allow for galvanizing elements approximately 13-15 meters, while specialized installations exceed 18 meters. In practice, many bridge structures, load-bearing frames, and columns exceed these values. In such cases, we use a double-dipping technique. The component is introduced into the bath in stages, ensuring appropriate overlap of the galvanizing zones. This method of operation requires very precise control of time, temperature, and structure position. The boundary between the two dips must be designed so that the coating maintains continuity and a uniform structure along the entire length of the component.

Thermal problems and the risk of large-scale deformation

The temperature of the zinc bath poses a significant challenge for large and heavy structures. Massive components heat unevenly, and temperature differences between individual components can lead to local stresses. An additional factor is welding stresses, which can be released at high temperatures.

To reduce the risk of deformation, we employ a controlled heating and immersion rate. In selected cases, we utilize preheating of the elements and carefully select the appropriate suspension points. This prevents the structure from uncontrolled movement under its own weight, and ensures a stable galvanizing process along the entire length and cross-section of the element.

Durability, economy and ecology – comprehensive benefits of galvanizing

Hot dip galvanizing of large-scale structures provides protection that, depending on the working environment, reaches from a dozen to even several dozen years. We treat the zinc coating as a simultaneous physical barrier and electrochemical protection. The zinc takes over the corrosion process, while the steel remains protected even where the coating is damaged locally.

From an economic perspective, a major advantage is the lack of regular maintenance requirements. Compared to paint systems, the total life-cycle cost of the structure remains significantly lower. Furthermore, zinc is recyclable, and the longer durability of steel reduces raw material consumption and the frequency of infrastructure component replacement.

Modern galvanizing plant in Strumet

At Strumet, we have technological resources designed for galvanizing large and heavy structures. We operate on lines that allow for precise control of process parameters, and we utilize our own laboratory facilities and a team experienced in working with bridge, industrial, and energy structures. We approach each order individually, analyzing the structure's geometry, weight, and target operating conditions before the process begins.

Why choose hot dip galvanizing for large projects?

At Strumet, we galvanize large-scale structures in a carefully considered and controlled manner. We work with large components daily, so we know the importance of preparation, proper suspension, and stable bath parameters. We approach each structure individually, as with such dimensions, there's no room for formulas.

We deliver components with a zinc coating that remains durable for years of use and requires no subsequent repairs. If you plan to galvanize a large structure and want to with some effect, please contact us – we will talk specifically about your project.