Electroplating – this mysterious-sounding technology is playing a key role in transforming the automotive industry. In this article, we'll discover five surprising ways in which electroplating affects vehicles, giving them not only an aesthetically pleasing shine but also resistance to extreme conditions and long-lasting durability. It's a fascinating application of chemical processes that is redefining standards in the automotive industry!

In today's automotive world, technological innovations play a crucial role in ensuring the safety, efficiency, and durability of vehicles. One of these innovations is electroplating, an electrochemical process that has numerous applications in the automotive industry. In this article, we'll explore five incredible applications of electroplating in the automotive industry, learning how it impacts the quality and durability of our vehicles.

Do You Know How Galvanization Affects the Durability of Your Car? Discover 5 Fascinating Applications!

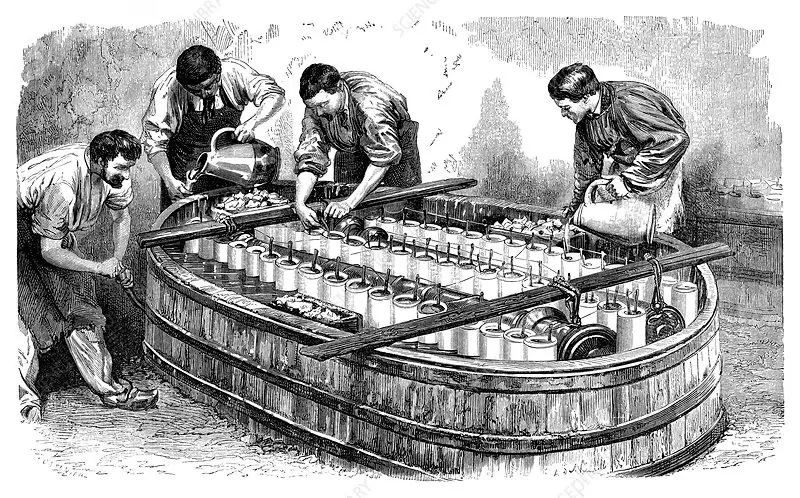

1. Corrosion protection

Let's start with the most obvious application of galvanization in the automotive industry – corrosion protection. Metal parts in cars are exposed to weathering and road salt. Therefore, manufacturers use galvanization, applying a thin layer of zinc to metal parts such as the body, chassis, or chassis. Zinc acts as a protective barrier, preventing corrosion and extending the life of the vehicle.

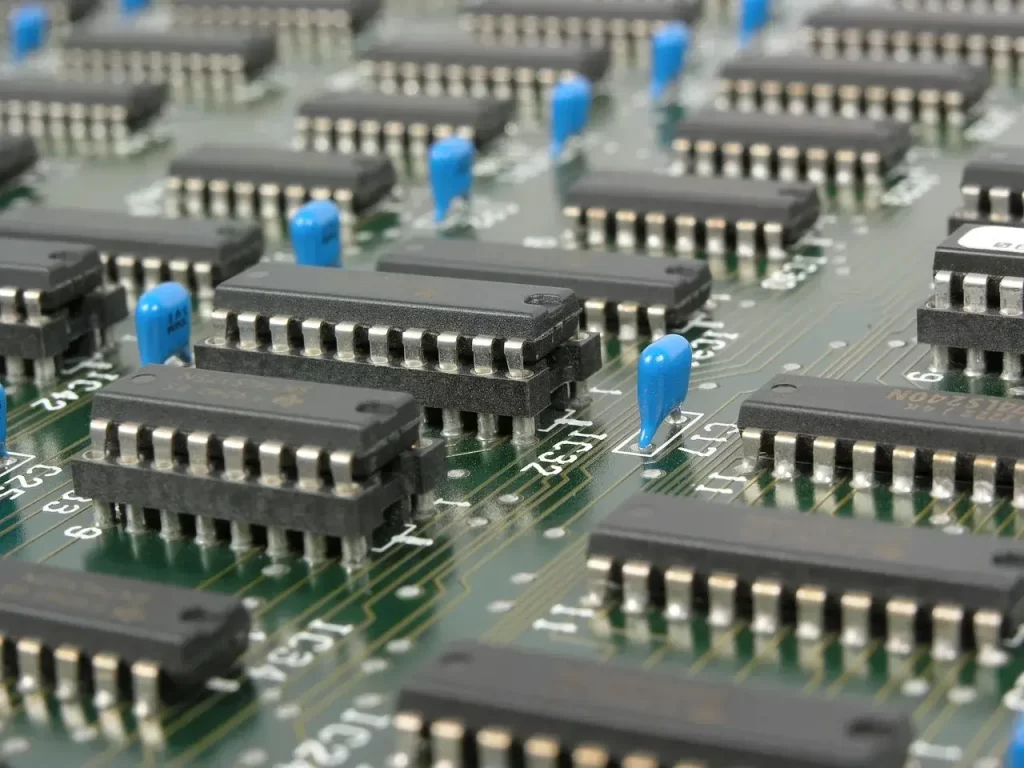

2. Improved electrical conductivity

In the automotive industry, where electronics play a key role, electrical conductivity is extremely important. Electroplating is used to improve electrical conductivity in electrical and electronic connections. Electroplating helps ensure stable current flow through various components, which is essential for the functioning of the electrical systems in the car.

3. Improving the aesthetics and durability of engine components

Engine components play a crucial role in the automotive industry, and the galvanizing process can significantly contribute to their performance and durability. Galvanizing provides components with a durable protective layer, which is crucial for preventing corrosion, especially important given the extreme conditions they are exposed to during engine operation. Therefore, galvanizing is a key step in the production of engine components, helping to maintain their performance, reliability, and aesthetics at the highest level for many years to come.

4. Battery production

Batteries are an essential part of every vehicle. The electroplating process is widely used in the production of automotive batteries. The zinc layer covering the battery plates increases the performance and durability of the battery, which translates into its longer service life.

5. Production of suspension components

Suspension components, such as springs and shock absorbers, must be exceptionally durable to ensure driving safety and comfort. Electroplating is used to coat these parts with a layer of zinc or other metals. which increases their resistance to corrosion and mechanical damage.

Summary

The use of electroplating in the automotive industry is incredibly versatile and offers numerous benefits, including corrosion protection, improved electrical conductivity, aesthetics and durability of engine components, battery production, and suspension components. These innovative solutions make cars more reliable and durable, which in turn translates into greater safety and travel comfort.

Using the services electroplating plant In the automotive industry, it's a prime example of how technology can support industry development, creating more advanced and durable products. That's why automakers continue to invest in research into new applications of this technology to meet growing consumer demands and safety standards. In the future, we can expect even more exciting applications of electroplating in the automotive industry, contributing to the continued growth of this industry.