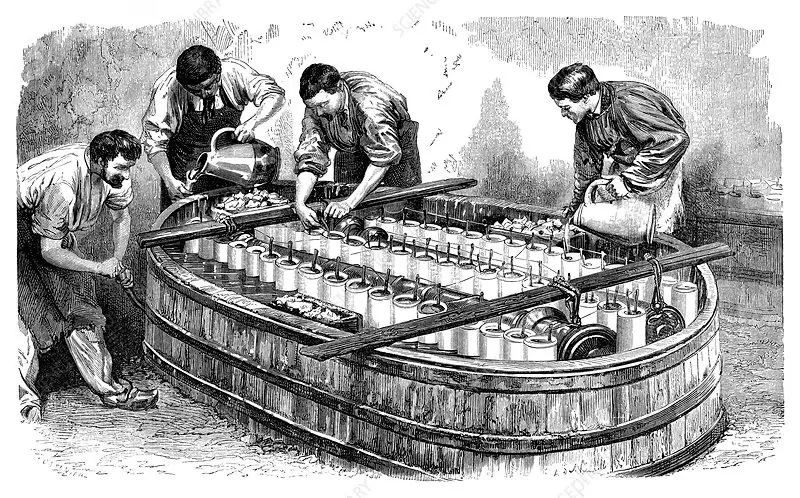

Galvanization is an electrochemical process that protects metal from corrosion by coating it with a layer of another metal, most often zinc. In today's article, we explore the different types of galvanization and why it is so important in industry and everyday life.

What is Galvanization?

Galvanization is a process in which one metal is used to protect another metal from corrosion.This is especially important for metals exposed to moisture and weathering. There are several different types of galvanization, each with its own application.

Types of Galvanization:

1. Galvanizing:

What is galvanizing?

Galvanizing is one of the most popular types of galvanization. It involves covering the metal with a layer of zinc.Zinc is exceptionally effective at preventing corrosion because it acts as a protective shield for the metal. It is widely used in the production of steel structures, cars, and many other items.

2. Chrome plating:

What is chrome plating?

Chrome plating is a process, in which chrome is applied to a metal surfaceChrome is not only corrosion-resistant but also adds aesthetic appeal to objects. That's why it's often used for automotive components, faucets, and tools.

3. Nickel plating:

Why is nickel plating used?

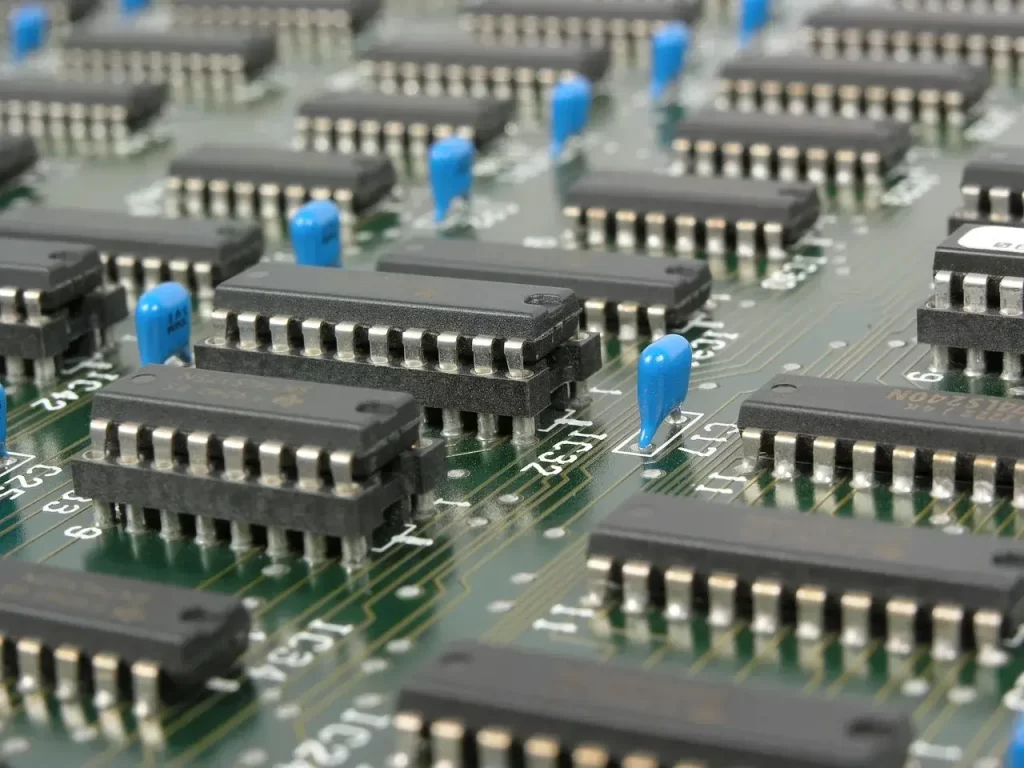

Nickel plating involves covering metal with a layer of nickel.Nickel is highly resistant to corrosion and gives the metal a smooth surface. It is commonly used in the electronics industry to coat contacts and transducers.

4. Tinning:

What are the applications of tinning?

Tinning involves covering metal with a layer of tin.It is primarily used to protect steel structures and manufacture electronic components. Tin is known for its durability and electrical conductivity.

Advantages and Applications of Galvanization

Galvanization has many advantages. Firstly, it protects the metal from corrosion, which extends the life of itemsSecondly, it gives the metals atraction lookThis is important both for structural elements and for products that are intended to be aesthetically pleasing.

Summary

In this article, we discussed the different types of electroplating, including zinc plating, chrome plating, nickel plating, and tin plating. Each type has its own unique properties and applications, but all serve to protect metal from corrosion. Electroplating is a key process in many industries, from automotive to electronics.

Therefore, it is worth learning about the different types of galvanization and choosing the one that best suits your project.

If you need galvanization services For your business, it's worth considering specialists in this field, such as Strumet. Our company offers top-quality galvanization services. Contact us to learn more about how we can help protect your metal products.