The zinc bath is the point at which the hot-dip galvanizing process transitions from preparation to actual steel protection. At Strumet, we consider this moment crucial to the durability of the entire coating. It is in the zinc bath that a reaction occurs, which cannot be corrected or improved at a later stage. Liquid zinc reacts directly with the steel surface, immediately revealing the quality of the material preparation, the stability of the process parameters, and the properties of the batch itself.

In hot dip galvanizing, the elements are immersed in molten zinc at a temperature of approximately 450°C, which leads to the formation of a permanent metallurgical bond. During the zinc bath zinc reacts with steel, as a result of which a system of Fe-Zn alloy layers is created, permanently bonded to the material. This prevents the coating from peeling or flaking, and maintains its integrity even in areas exposed to mechanical stress. This type of protection extends the service life of the steel by 25 to 100 years, depending on operating conditions.

What is a zinc bath and why is it a key element of metal protection?

The zinc bath does not simply cover the steel with a metal layer, because during the process, a diffusion process occurs between iron and zinc, which leads to the formation of several characteristic Fe-Zn alloy layers. Each of them is responsible for different material properties of the coating, ranging from mechanical resistance after electrochemical protection. The deepest alloy layers are characterized by high hardness and abrasion resistance, while the outer layer of pure zinc plays the role anodic protectionj. Zinc undergoes controlled wear and takes over the corrosion process, so the steel remains protected even if the coating is damaged locally. For this reason, we use hot-dip galvanizing in structures intended for long-term operation in difficult environmental conditions.

Mechanical preparation - abrasive blasting before bathing

The zinc bath process is preceded by thorough mechanical preparation. Abrasive blasting removes mill scale, corrosion products, and remnants of previous protective coatings. We use abrasive materials such as cast steel or cast iron, which effectively clean the surface and give it the appropriate roughness.

Roughness This has a direct impact on the course of the reaction in the zinc bath. A surface that is too smooth limits the initiation of diffusion, while an excessively uneven surface promotes the uncontrolled growth of alloy layers. In practice, we observe that differences in mechanical preparation can cause noticeable discrepancies in coating thickness, despite identical bath parameters.

For smaller components or parts with specific geometries, we accept alternative preparation methods, such as vibro-abrasive machining or tumbling. Regardless of the method, the zinc bath requires a surface free of scale and contamination, because only then the reaction of iron with zinc takes place evenly.

Chemical cleaning – degreasing and etching of surfaces

After mechanical preparation, we move on to the chemical stage. Degreasing We remove oils, greases, and organic residues that would block direct contact between zinc and steel. We then etch (usually in hydrochloric acid) to eliminate iron oxides and non-metallic residues created during rolling and storage. Digestion determines the reactivity of the surface in the zinc bath. Under-etched steel reacts with zinc more slowly and unevenly, leading to local differences in the coating structure. Excessive etching, on the other hand, leads to faster growth of alloy layers and increased brittleness – therefore, chemical cleaning parameters are always selected based on the steel grade and its chemical composition.

Rinsing and Fluxing – Key Procedures Before Zinc Dipping

After pickling, we proceed to thoroughly rinsing the components, as this is the moment when we determine whether the surface will enter the zinc bath in a state of chemical equilibrium. We remove residual acids and chlorides, which, upon contact with the liquid zinc, could cause local reaction disturbances and visible coating defects. Proper rinsing significantly reduces the risk of blistering, porosity, and discontinuity in the zinc layer.

Immediately after rinsing we move on to fluxing and immerse the steel in a solution of zinc chloride and ammonium chloride. At this stage, we prepare the surface for contact with the liquid metal and protect it from re-oxidation. We know from experience that the quality of the fluxing is quickly revealed in the coating's structure. On components with complex geometry and in hard-to-reach areas, this stage determines whether the zinc will distribute evenly and create a cohesive, stable layer.

Drying parts – why is temperature so important for the zinc bath?

Drying is carried out at temperatures 120-150°C and we monitor both the temperature itself and the heating rate of the detail. Heating too quickly weakens the flux layer., and too slow promotes chemical reactions that should not occur before the zinc bath. A well-dried element enters the liquid zinc in a state that allows for controlled diffusion, which translates into an even coating structure and stable growth of alloy layers from the very first moments of the process.

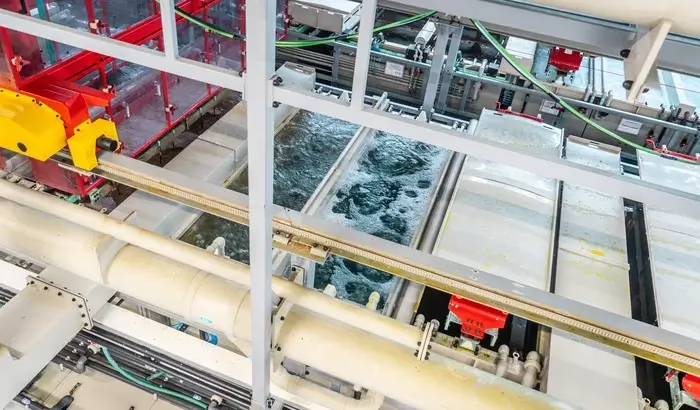

The zinc bath proper – formation of the coating and iron-zinc alloy

The zinc coating process begins by immersing the components in molten zinc at a temperature of 445-455°C. Within a few dozen seconds subsequent alloy layers are created, and their thickness and structure depend on the immersion time, bath temperature, and chemical composition of the steel. For components such as screws and nuts, we work at elevated temperatures, reaching approximately 560°C, which allows us to maintain control over the coating growth and maintain proper application tolerances. We pay particular attention to silicon and phosphorus content, because they have the greatest impact on the reaction rate and the structure of the alloy layers. We consciously control the process parameters to ensure that the coating does not grow excessively and that its structure maintains mechanical resistance and stability over the long term.

Ecology and economy – why choose hot-dip galvanizing?

A zinc bath allows steel to be protected in a single process for many years, without the need for periodic painting or frequent maintenance. In practice, this means less use of protective materials and less interference with finished structures over many years of use.

At Strumet, we conduct hot-dip galvanizing in controlled, closed-loop processes, with energy recovery and constant process monitoring. For years, we have been protecting tens of thousands of tons of steel per year, and we put the structures into service with a zinc coating that can easily withstand long-term use in demanding environments.